品牌

其他厂商性质

所在地

产品概述

YG系列立式离心泵是安装使用方便,泵轴同心度及叶轮的动静平衡,保证了运行时无动静、低噪音。采用碳化硅,氟橡硬质合金机械密封,泵体过流部分壁厚加厚能保证静压高的循环系统正常使用

产品用途

1.YG泵输送油类或易燃、易爆液体,如柴油、汽油、煤油等。

2.该泵主要使用在管路增压,远距离输送汽油、煤油、柴油、航空油等油类,也可输送其它无腐蚀性的液体。 介质温度为-20℃~80℃。适用于油库、油站、化工、矿山、石化、企事业单位等。

工作条件

流量: 2~1400m 3 /h 扬程:5~130m

工作温度:-20℃ ~+ 100℃

防护等级:IP44或IP54 环境温度:≤+40℃

电机类型:YB

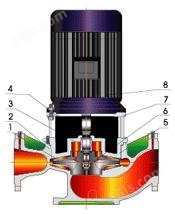

结构图

| 序号 | 部件名称 | 序号 | 部件名称 |

|---|---|---|---|---|

| 1 | 叶轮 | 5 | 端盖 | |

| 2 | 泵体 | 6 | 叶轮螺母 | |

| 3 | 机械密封 | 7 | 泵轴 | |

| 4 | 挡水圈 | 8 | 电机(防爆) |

性能参数表

| 型号 Model | 流量 Flow (m 3 /h) | 扬程Head (m) | 转速 Speed (r/min) | 功率 Power (KW) | 电压Voltage (V) | 汽蚀余量NPSHr | 重量Weight (kg) |

|---|---|---|---|---|---|---|---|

| 20-160 | 2 | 32 | 2900 | 0.75 | 380 | 2.3 | 38 |

| 25-125 | 3 | 20 | " | 0.75 | " | 2.3 | 35 |

| 25-160 | 3 | 32 | " | 1.1 | " | 2.3 | 44 |

| 25-160A | 2.6 | 25 | " | 0.75 | " | 2.3 | 40 |

| 32-125 | 4.5 | 20 | " | 0.75 | " | 2.3 | 38 |

| 32-160 | 4.5 | 32 | " | 1.5 | " | 2.3 | 49 |

| 32-160A | 4 | 25 | " | 1.1 | " | 2.3 | 43 |

| 32-200 | 4.5 | 50 | " | 3 | " | 2.3 | 68 |

| 32-200A | 4 | 40 | " | 2.2 | " | 2.3 | 58 |

| 40-100 | 6.3 | 12.5 | " | 0.75 | " | 2.3 | 36 |

| 40-125 | 6.3 | 20 | " | 1.1 | " | 2.3 | 45 |

| 40-125A | 5.5 | 16 | " | 0.75 | " | 2.3 | 38 |

| 40-160 | 6.3 | 32 | " | 2.2 | " | 2.3 | 52 |

| 40-160A | 5.5 | 25 | " | 1.5 | " | 2.3 | 42 |

| 40-200 | 6.3 | 50 | " | 4 | " | 2.3 | 79 |

| 40-200A | 5.5 | 40 | " | 3 | " | 2.3 | 67 |

| 40-250 | 6.3 | 80 | " | 7.5 | " | 2.3 | 123 |

| 40-250A | 5.5 | 65 | " | 5.5 | " | 2.3 | 115 |

| 40-100(I) | 12.5 | 12.5 | " | 0.75 | " | 2.3 | 40 |

| 40-125(I) | 12.5 | 20 | " | 1.5 | " | 2.3 | 47 |

| 40-125(I)A | 10.5 | 16 | " | 1.1 | " | 2.3 | 40 |

| 40-160(I) | 12.5 | 32 | " | 3 | " | 2.3 | 67 |

| 40-160(I)A | 10.5 | 25 | " | 2.2 | " | 2.3 | 56 |

| 40-200(I) | 12.5 | 50 | " | 5.5 | " | 2.3 | 110 |

| 40-200(I)A | 10.5 | 40 | " | 4 | " | 2.3 | 88 |

| 40-250(I) | 12.5 | 80 | " | 11 | " | 2.3 | 175 |

| 40-250(I)A | 10.5 | 65 | " | 7.5 | " | 2.3 | 125 |

| 50-100 | 12.5 | 12.5 | " | 0.75 | " | 2.3 | 39 |

| 50-125 | 12.5 | 20 | " | 1.5 | " | 2.3 | 49 |

| 50-125A | 10.5 | 16 | " | 1.1 | " | 2.3 | 42 |

| 50-160 | 12.5 | 32 | " | 3 | " | 2.3 | 68 |

| 50-160A | 10.5 | 25 | " | 2.2 | " | 2.3 | 58 |

| 50-200 | 12.5 | 50 | " | 5.5 | " | 2.3 | 108 |

| 50-200A | 10.5 | 40 | " | 4 | " | 2.3 | 88 |

| 50-250 | 12.5 | 80 | " | 11 | " | 2.3 | 175 |

| 50-250A | 10.5 | 65 | " | 7.5 | 2.3 | 125 | |

| 50-100(I) | 25 | 12.5 | " | 1.5 | " | 2.5 | 55 |

| 50-100(I)A | 20 | 10 | " | 1.1 | " | 2.5 | 48 |

| 50-125(I) | 25 | 20 | " | 2.2 | " | 2.5 | 76 |

| 50-125(I)A | 20 | 16 | " | 1.5 | " | 2.5 | 66 |

| 50-160(I) | 25 | 32 | " | 4 | " | 2.5 | 85 |

| 50-160(I)A | 20 | 25 | " | 3 | " | 2.5 | 84 |

| 50-200(I) | 25 | 50 | " | 7.5 | " | 2.5 | 146 |

| 50-200(I)A | 20 | 40 | " | 5.5 | " | 2.5 | 144 |

| 50-250(I) | 25 | 80 | " | 15 | " | 2.5 | 193 |

| 50-250(I)A | 20 | 65 | " | 11 | " | 2.5 | 182 |

| 50-315(I) | 25 | 125 | " | 30 | " | 2.5 | 330 |

| 50-315(I)A | 20 | 100 | " | 22 | " | 2.5 | 270 |